- Home

- About us

- Products

- Services

- Contact us

- Downloads

- Company Profile

- PeeVee Catalogue

- Threaded Repair Catalogue Powercoil

- Black Oxide Surface Finish

- Fastener Markings - Bolts

- Fastener Markings - Nuts

- Nuts - Mechanical Requirements

- Chemical Component of Studs

- Common Abbreviations

- Mechanical Requirements Metric

- Conversion Chart

- Thread Terminology

- Terms & Conditions

- Downloads Video

- News

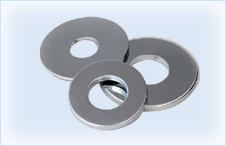

Flat washers in standard carbon steel and in through hardened steel (also see EMP's Tech Bulletin on " Hardened Washers").

Flat washers in standard carbon steel and in through hardened steel (also see EMP's Tech Bulletin on " Hardened Washers"). Earnest standard carbon steel line consists of two styles of washers:

• SAE Washers (also called Narrow Series per ASME B18.22.1 Type A)

• USS Washers (also called Wide Series" per ASME B18.22.1 Type A)

Earnest recommends the use of standard carbon steel washers on low strength assemblies (grade 2 or 5) where a flat smooth surface is required that will distribute the load over a wide area. For high strength and critical assembles Earnest recommends the use of a hardened washer.

Earnest carbon steel line of washers are made from low carbon steel. Typical hardness is Rb 70/85.

Washers are available with a plain finish or zinc plated with a clear chromate (silver color) or with a yellow chromate (bronze to gold color) for superior corrosion protection.

Washers are designed to provide a smooth bearing surface for the bolt and nut to clamp down onto and to distribute the load evenly over larger areas under the head and nut

The use of the largest OD washer that will fit in the application will help ensure that the clamp load is spread over the largest bearing area, which results in an assembly that resist loosening and prevent failures from occurring.

• SAE Washers (also called Narrow Series per ASME B18.22.1 Type A)

• USS Washers (also called Wide Series" per ASME B18.22.1 Type A)

• F436 Structural Washers (per ASTM F436)

• Plow Bolt Washers

All four styles of washers are made from carbon steel and heat treated to a hardness of Rc 38/45 (F436 washers in sizes over 1 1/2" may be case hardened).

The use of the largest OD washer that will fit in the application will help ensure that the clamp load is spread over the largest bearing area, which results in an assembly that resist loosening and prevent failures from occurring.

011-49098640

011-49098640